New-UXTM

Remanufacturing Facility Services with PowerRail

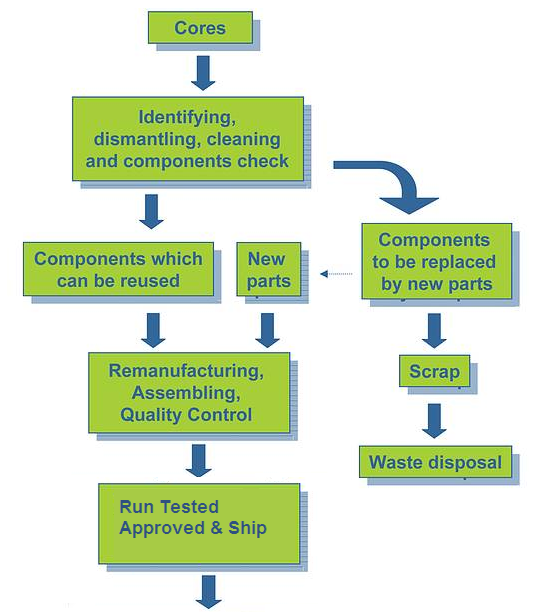

PowerRail also offers the largest line of Remanufactured parts and components for all locomotives, young and old. Our product line offers our traditional “TrueBlue Series™” Unit Exchange (UX) or Customers Repair & Return programs. In an effort to offer our customer True Reliability and Extended Life we now offer our New Program of “New-UX™. All components are manufactured to meet or exceed not only the OEM specs, but must meet our rigorous internal M-1003 AAR Quality inspections. We have the flexibility and resources to provide Finished Locomotive parts utilizing our Internal Manufacturing Facility’s Experience and Knowledge coupled with resources of both Materials and Techniques throughout the world.

Rebuild Reliability

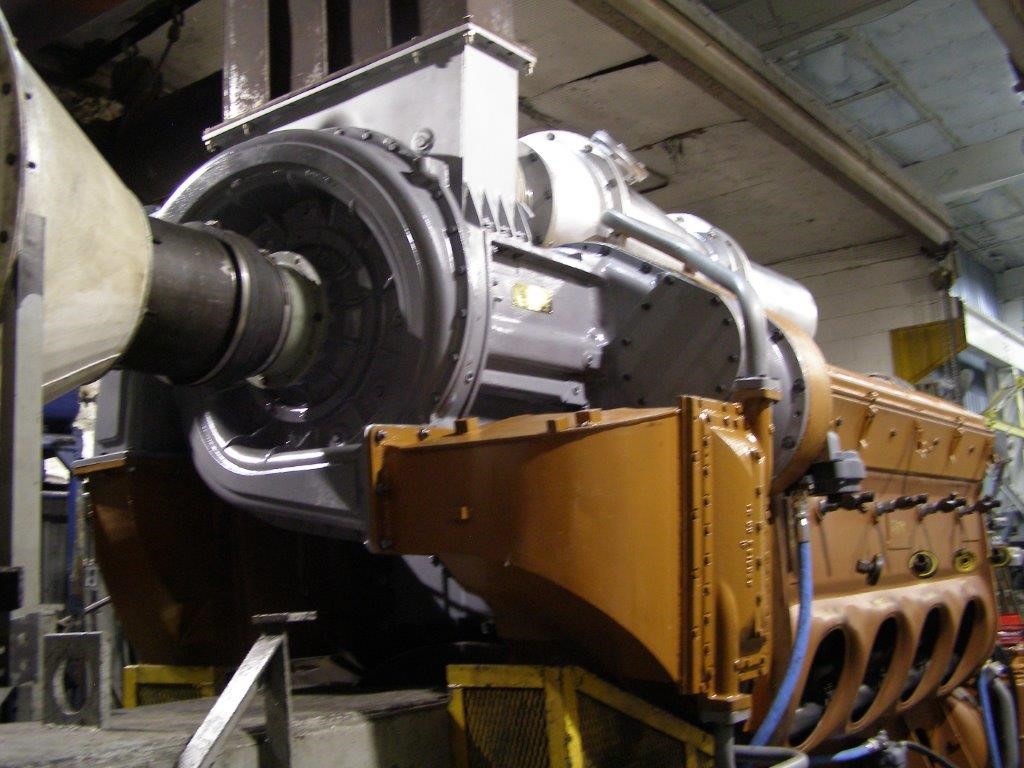

PowerRail strives to provide a highly reliable product to the end user. For this reason, coupled with our M-1003 Quality program, PowerRail's rebuild facilities follow a strict testing procedure; including test cells which actually duplicate locomotive loads to ensure the product will endure its expected life cycle. The time, money and resources PowerRail has invested into this procedure is all for the benefit of Our Customers.

Starter Test Cell Utilizes actual

645 Engine Flywheel |

Recently Renovated Engine Dyno

for both Mechanical and

Electronic Injectors

|

Roots Blower Cell

actually runs blowers with Oil

|

Rebuild Work Instructions and MI’s

Unlike our competition, PowerRail is striving to provide a highly reliable product to the end user. For this reason, coupled with our M-1003 Quality program, PowerRail's rebuild facilities all have a paperless system so we can ensure the build cycle is to the latest engineering revision. In addition, this system will enhance the operators knowledge and train for perfection.

Experienced

Because we have many years of experience in thousands of parts and components, you can rest assured that we understand your specific needs for Quality and Reliability. We offer a qualified, professional workforce combined with proven manufacturing facilities and leading-edge technology. We understand that speed to market is a focus for you, and we cater our services to meet your demanding schedule. We have maximized our facility’s focus and increased operating efficiencies, created more Synergies and Partnered Manufacturing making it easy to meet your requirements. We have a diverse company footprint that allows us to offer you a wide range of products in a timely manner. This experience has also allowed us to manufacture more products in North America while offering a true family of employees that have skills and dedication.